Page 78 - Tube Tool Catalogue

P. 78

Sugar Mill Tube Cleaners

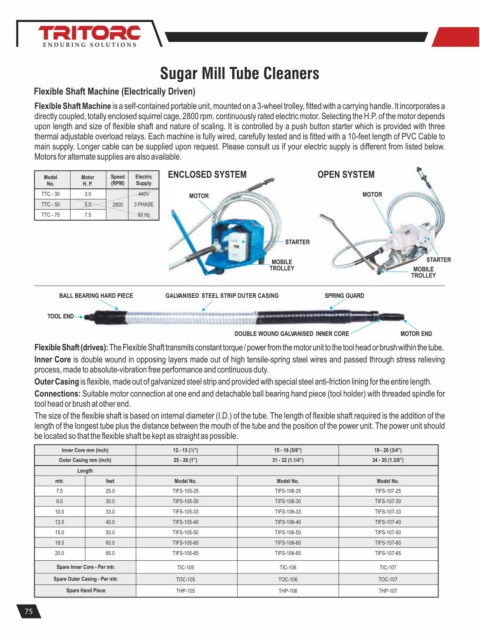

Flexible Shaft Machine (Electrically Driven)

Flexible Shaft Machine is a self-contained portable unit, mounted on a 3-wheel trolley, fitted with a carrying handle. It incorporates a

directly coupled, totally enclosed squirrel cage, 2800 rpm. continuously rated electric motor. Selecting the H.P. of the motor depends

upon length and size of flexible shaft and nature of scaling. It is controlled by a push button starter which is provided with three

thermal adjustable overload relays. Each machine is fully wired, carefully tested and is fitted with a 10-feet length of PVC Cable to

main supply. Longer cable can be supplied upon request. Please consult us if your electric supply is different from listed below.

Motors for alternate supplies are also available.

Model Motor Speed Electric ENCLOSED SYSTEM OPEN SYSTEM

No. H. P. (RPM) Supply

TTC - 30 3.0 440V MOTOR MOTOR

TTC - 50 5.0 2800 3 PHASE

TTC - 75 7.5 50 Hz

STARTER

MOBILE STARTER

TROLLEY MOBILE

TROLLEY

BALL BEARING HARD PIECE GALVANISED STEEL STRIP OUTER CASING SPRING GUARD

TOOL END

DOUBLE WOUND GALVANISED INNER CORE MOTOR END

Flexible Shaft (drives): The Flexible Shaft transmits constant torque / power from the motor unit to the tool head or brush within the tube.

Inner Core is double wound in opposing layers made out of high tensile-spring steel wires and passed through stress relieving

process, made to absolute-vibration free performance and continuous duty.

Outer Casing is flexible, made out of galvanized steel strip and provided with special steel anti-friction lining for the entire length.

Connections: Suitable motor connection at one end and detachable ball bearing hand piece (tool holder) with threaded spindle for

tool head or brush at other end.

The size of the flexible shaft is based on internal diameter (I.D.) of the tube. The length of flexible shaft required is the addition of the

length of the longest tube plus the distance between the mouth of the tube and the position of the power unit. The power unit should

be located so that the flexible shaft be kept as straight as possible.

Inner Core mm (inch) 12 - 13 (½”) 15 - 16 (5/8”) 19 - 20 (3/4”)

Outer Casing mm (inch) 25 - 26 (1”) 31 - 32 (1.1/4”) 34 - 35 (1.3/8”)

Length

mtr. feet Model No. Model No. Model No.

7.5 25.0 TIFS-105-25 TIFS-106-25 TIFS-107-25

9.0 30.0 TIFS-105-30 TIFS-106-30 TIFS-107-30

10.0 33.0 TIFS-105-33 TIFS-106-33 TIFS-107-33

12.0 40.0 TIFS-105-40 TIFS-106-40 TIFS-107-40

15.0 50.0 TIFS-105-50 TIFS-106-50 TIFS-107-50

18.0 60.0 TIFS-105-60 TIFS-106-60 TIFS-107-60

20.0 65.0 TIFS-105-65 TIFS-106-65 TIFS-107-65

Spare Inner Core - Per mtr. TIC-105 TIC-106 TIC-107

Spare Outer Casing - Per mtr. TOC-105 TOC-106 TOC-107

Spare Hand Piece THP-105 THP-106 THP-107

75