Page 2 - Tube Tool Catalogue

P. 2

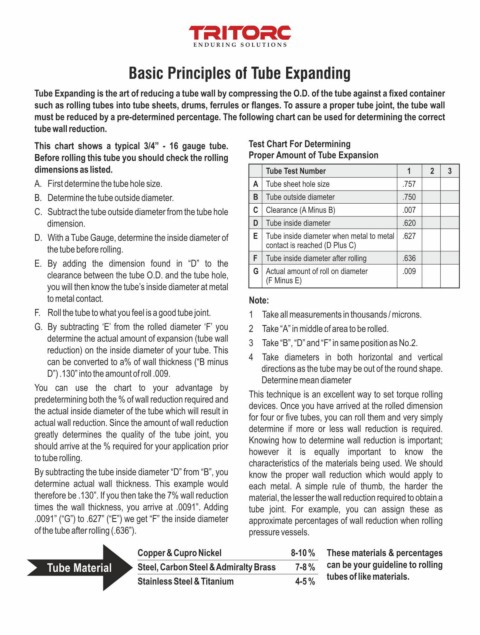

Basic Principles of Tube Expanding

Tube Expanding is the art of reducing a tube wall by compressing the O.D. of the tube against a fixed container

such as rolling tubes into tube sheets, drums, ferrules or flanges. To assure a proper tube joint, the tube wall

must be reduced by a pre-determined percentage. The following chart can be used for determining the correct

tube wall reduction.

This chart shows a typical 3/4” - 16 gauge tube. Test Chart For Determining

Before rolling this tube you should check the rolling Proper Amount of Tube Expansion

dimensions as listed. Tube Test Number 1 2 3

A. First determine the tube hole size. A Tube sheet hole size .757

B. Determine the tube outside diameter. B Tube outside diameter .750

C. Subtract the tube outside diameter from the tube hole C Clearance (A Minus B) .007

dimension. D Tube inside diameter .620

D. With a Tube Gauge, determine the inside diameter of E Tube inside diameter when metal to metal .627

the tube before rolling. contact is reached (D Plus C)

F Tube inside diameter after rolling .636

E. By adding the dimension found in “D” to the

G Actual amount of roll on diameter .009

clearance between the tube O.D. and the tube hole,

(F Minus E)

you will then know the tube’s inside diameter at metal

to metal contact. Note:

F. Roll the tube to what you feel is a good tube joint. 1 Take all measurements in thousands / microns.

G. By subtracting ‘E’ from the rolled diameter ‘F’ you 2 Take “A” in middle of area to be rolled.

determine the actual amount of expansion (tube wall

3 Take “B”, “D” and “F” in same position as No.2.

reduction) on the inside diameter of your tube. This

4 Take diameters in both horizontal and vertical

can be converted to a% of wall thickness (“B minus

directions as the tube may be out of the round shape.

D”) .130” into the amount of roll .009.

Determine mean diameter

You can use the chart to your advantage by

This technique is an excellent way to set torque rolling

predetermining both the % of wall reduction required and

the actual inside diameter of the tube which will result in devices. Once you have arrived at the rolled dimension

for four or five tubes, you can roll them and very simply

actual wall reduction. Since the amount of wall reduction

determine if more or less wall reduction is required.

greatly determines the quality of the tube joint, you

Knowing how to determine wall reduction is important;

should arrive at the % required for your application prior

however it is equally important to know the

to tube rolling.

characteristics of the materials being used. We should

By subtracting the tube inside diameter “D” from “B”, you know the proper wall reduction which would apply to

determine actual wall thickness. This example would each metal. A simple rule of thumb, the harder the

therefore be .130”. If you then take the 7% wall reduction material, the lesser the wall reduction required to obtain a

times the wall thickness, you arrive at .0091”. Adding tube joint. For example, you can assign these as

.0091” (“G”) to .627” (“E”) we get “F” the inside diameter approximate percentages of wall reduction when rolling

of the tube after rolling (.636”). pressure vessels.

Copper & Cupro Nickel 8-10 % These materials & percentages

Tube Material Steel, Carbon Steel & Admiralty Brass 7-8 % can be your guideline to rolling

tubes of like materials.

Stainless Steel & Titanium 4-5 %