Page 3 - HOT TAPPING CATALOG

P. 3

HOT TAPPING & FLOW STOPPING

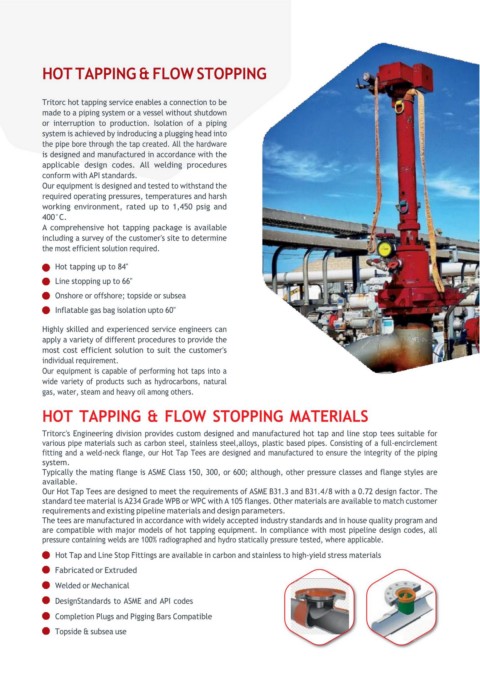

Tritorc hot tapping service enables a connection to be

made to a piping system or a vessel without shutdown

or interruption to production. Isolation of a piping

system is achieved by indroducing a plugging head into

the pipe bore through the tap created. All the hardware

is designed and manufactured in accordance with the

applicable design codes. All welding procedures

conform with API standards.

Our equipment is designed and tested to withstand the

required operating pressures, temperatures and harsh

working environment, rated up to 1,450 psig and

400°C.

A comprehensive hot tapping package is available

including a survey of the customer's site to determine

the most efficient solution required.

Hot tapping up to 84"

Line stopping up to 66"

Onshore or offshore; topside or subsea

Inflatable gas bag isolation upto 60"

Highly skilled and experienced service engineers can

apply a variety of different procedures to provide the

most cost efficient solution to suit the customer's

individual requirement.

Our equipment is capable of performing hot taps into a

wide variety of products such as hydrocarbons, natural

gas, water, steam and heavy oil among others.

HOT TAPPING & FLOW STOPPING MATERIALS

Tritorc's Engineering division provides custom designed and manufactured hot tap and line stop tees suitable for

various pipe materials such as carbon steel, stainless steel,alloys, plastic based pipes. Consisting of a full-encirclement

fitting and a weld-neck flange, our Hot Tap Tees are designed and manufactured to ensure the integrity of the piping

system.

Typically the mating flange is ASME Class 150, 300, or 600; although, other pressure classes and flange styles are

available.

Our Hot Tap Tees are designed to meet the requirements of ASME B31.3 and B31.4/8 with a 0.72 design factor. The

standard tee material is A234 Grade WPB or WPC with A 105 flanges. Other materials are available to match customer

requirements and existing pipeline materials and design parameters.

The tees are manufactured in accordance with widely accepted industry standards and in house quality program and

are compatible with major models of hot tapping equipment. In compliance with most pipeline design codes, all

pressure containing welds are 100% radiographed and hydro statically pressure tested, where applicable.

Hot Tap and Line Stop Fittings are available in carbon and stainless to high-yield stress materials

Fabricated or Extruded

Welded or Mechanical

DesignStandards to ASME and API codes

Completion Plugs and Pigging Bars Compatible

Topside & subsea use